What stands in the way of optimal production?

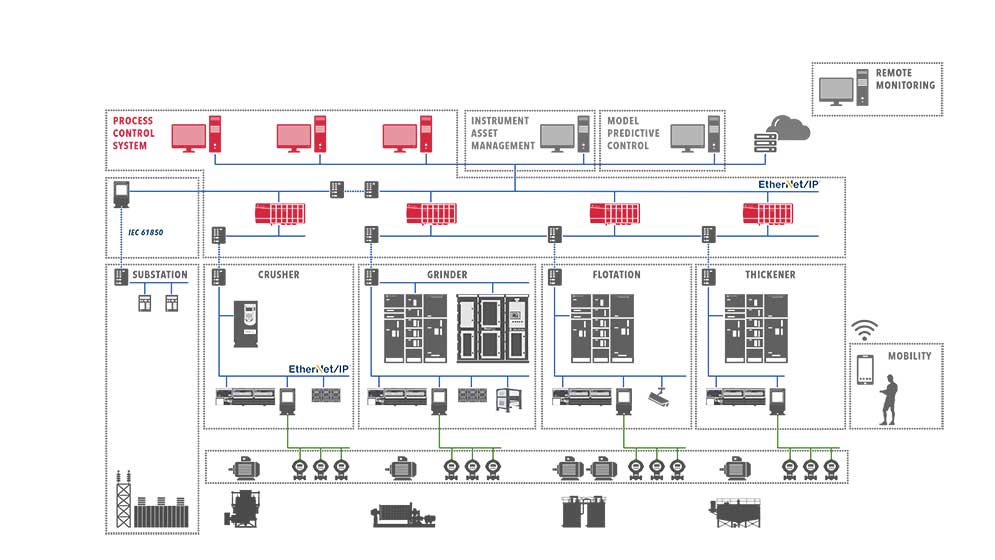

Process Solutions

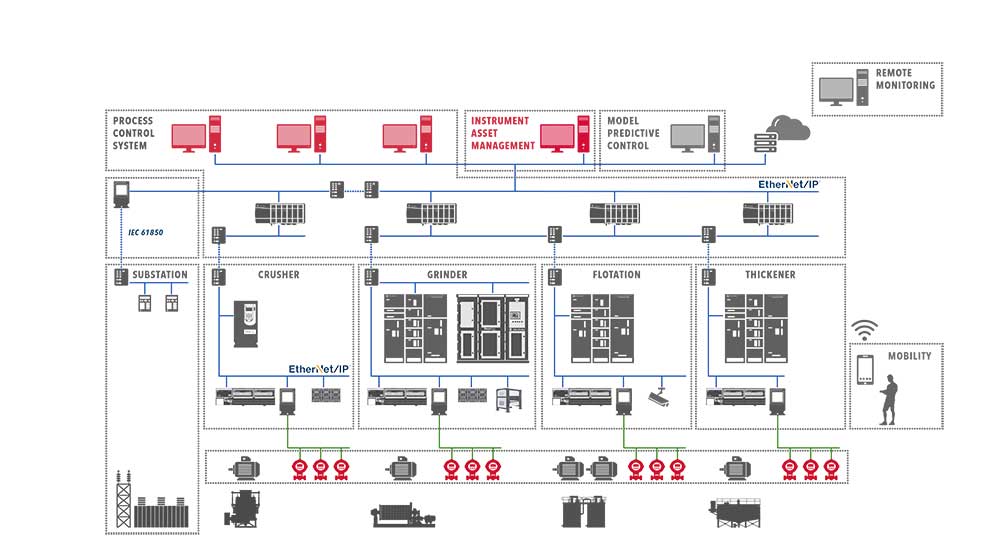

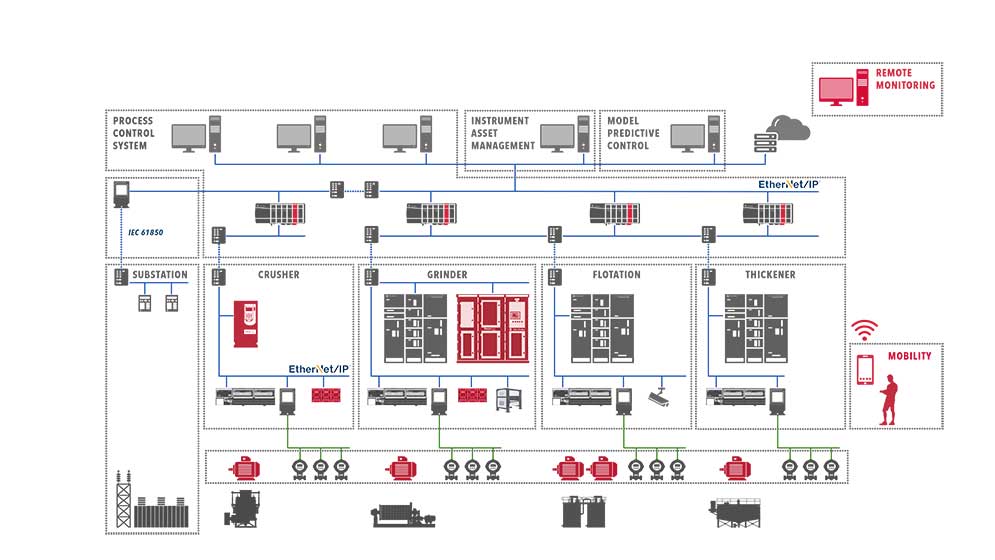

With integrated process control, safety, motor control and analytics, our architectures deliver benefits across mining operations, including in mineral processing plants.

Purpose-built process control is at the core of our mining architecture. Built on our PlantPAx ® distributed control system (DCS), it delivers pre-engineered content for mine control, monitoring and reporting. It also includes modules developed for mining-specific challenges, including flotation level control.

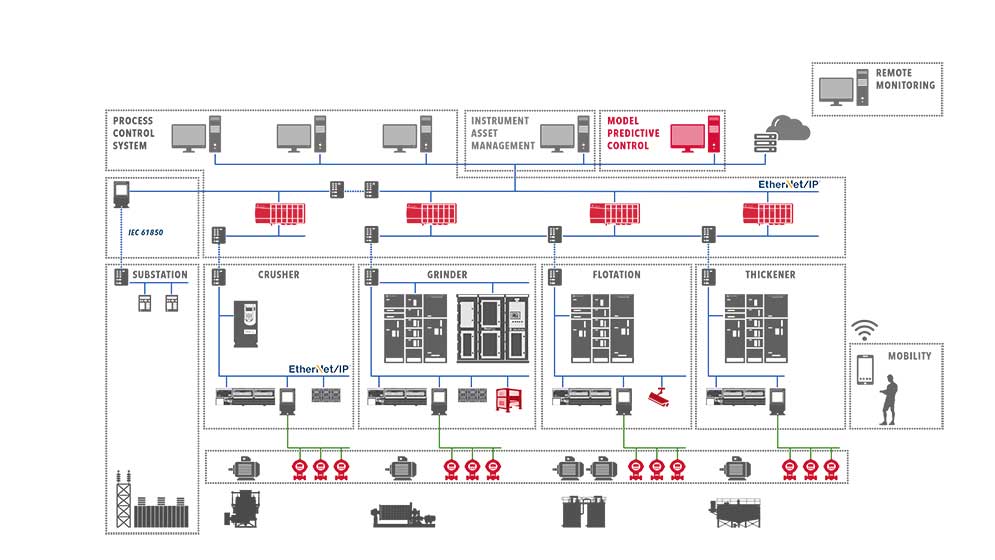

Process Optimization

To improve complex, multivariable processes, choose Logix or software-based model predictive control (MPC) solutions. MPC strategies can simultaneously track and optimize multiple applications, handle restrictions and constraints – and manage variability.

The result?

- Better process stability

- Increased recovery

- Less reagent consumption

- Lower energy usage and costs

- Better throughput

High-Performance, End-to-End Connectivity

Our EtherNet/IP™ network infrastructure enables system integration across the processing plant and convergence of information technology (IT) and operations technology (OT). So you can design a single, secure and unified network that allows seamless connectivity and information sharing across your mining operations.

Reduce project risk, decrease engineering and maintenance costs – and keep your information moving – with a system that is…

- Tested: Built on validated Converged Plantwide Ethernet (CPwE) reference architectures.

- Flexible: Seamlessly connects with Rockwell Automation products as well as third-party devices, including field instrumentation.

- Fast: Able to meet real-time communication requirements.

- Secure: With integrated security specifically configured for control system networks to protect your vital assets.

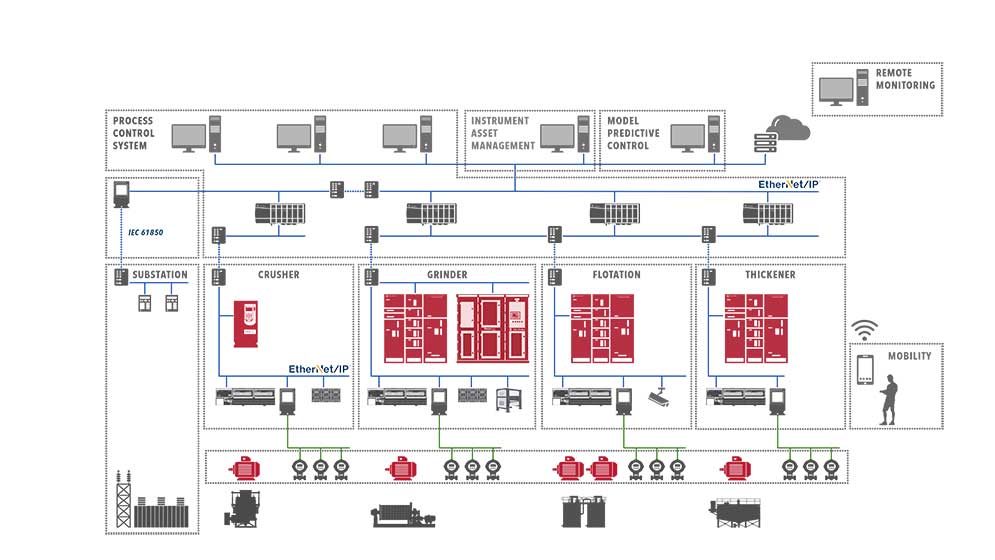

Smart Motor Control

Your processing plant relies on efficient motor operation to maintain throughput – and stay profitable. By unifying power and process control information, our Integrated Architecture provides the visibility you need to quickly identify issues and act.

Smart motor control solutions help optimize applications throughout your plant’s lifecycle.

- Streamline CENTERLINE® MCC setup – and quickly monitor and troubleshoot your system – thanks to IntelliCENTER® software and EtherNet/IP connectivity.

- Enhance crusher and grinder reliability, improve performance, simplify commissioning and ease maintenance with on-board analytics in our PowerFlex® MV and LV drives.

Smart Devices

Managing the vast number of instruments across your plant is challenging. Our partnership with Endress + Hauser means you can easily integrate, configure and monitor devices within your control system.

- Reduce engineering time with pre-engineered faceplates and standard configuration.

- Streamline commissioning and setup with seamless network integration for EtherNet/IP native instruments – and HART, Wireless HART, Profibus PA, and Foundation Fieldbus devices.

- Decrease maintenance costs and improve efficiency by configuring and managing field devices centrally using E+H Fieldcare.

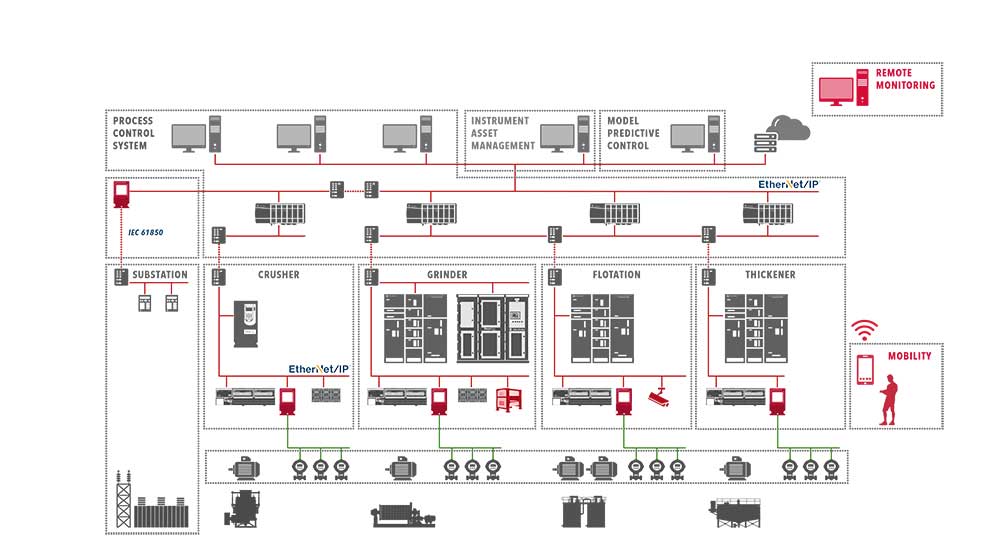

Intelligent Asset Optimization

To drive asset improvements, you need access to the right information at the right time. You also need better ways to connect data.

We provide information-enabled solutions from device to enterprise:

- Dynamix™ integrated condition monitoring helps detect potential equipment failures before they occur.

- PowerFlex drives can enable predictive maintenance and minimize unplanned downtime by calculating the expected life of components based on actual operating conditions.

- FactoryTalk® Analytics™ LogixAI™ modules provide embedded analytics close to the equipment – no data scientist required.

- FactoryTalk InnovationSuite brings the power of the Industrial Internet of Things (IIoT) to your operations. Analyze equipment performance, predict failures and use augmented reality (AR) to provide real-time information to the field and enable remote collaboration.

Compressed air is the preferred energy source for a wide range of mining applications.

But meeting demand efficiently and safely can be difficult – especially when managing a multi-compressor system.

Compressor Control

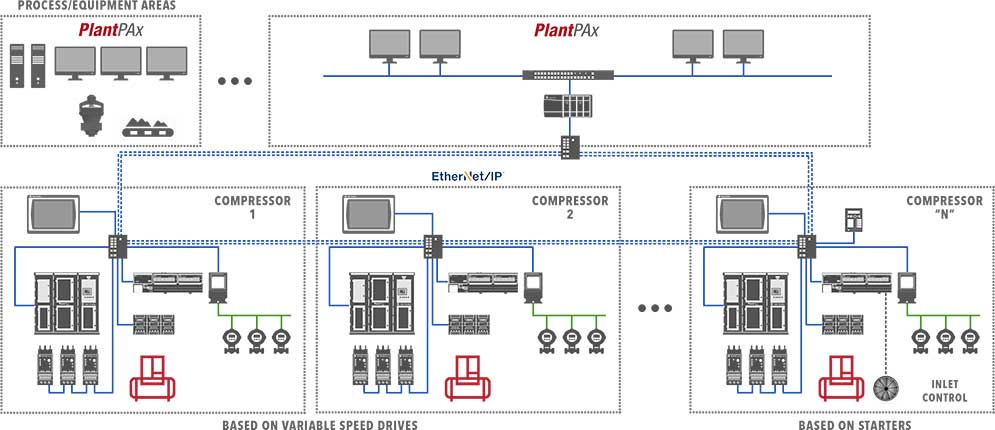

With integrated process control, safety, motor control and analytics, our architectures deliver benefits across mining operations, including compressed air systems.

Purpose-built process control is at the core of our mining architecture. Built on our PlantPAx® distributed control system (DCS), it delivers pre-engineered content for mine control, monitoring and reporting. It also incorporates modules developed for mining-specific challenges, including coordinated multi-compressor control and integrated anti-surge protection.

Unlike proprietary solutions, our compressor solution is built on a standard, open platform aligned with your other mining applications.

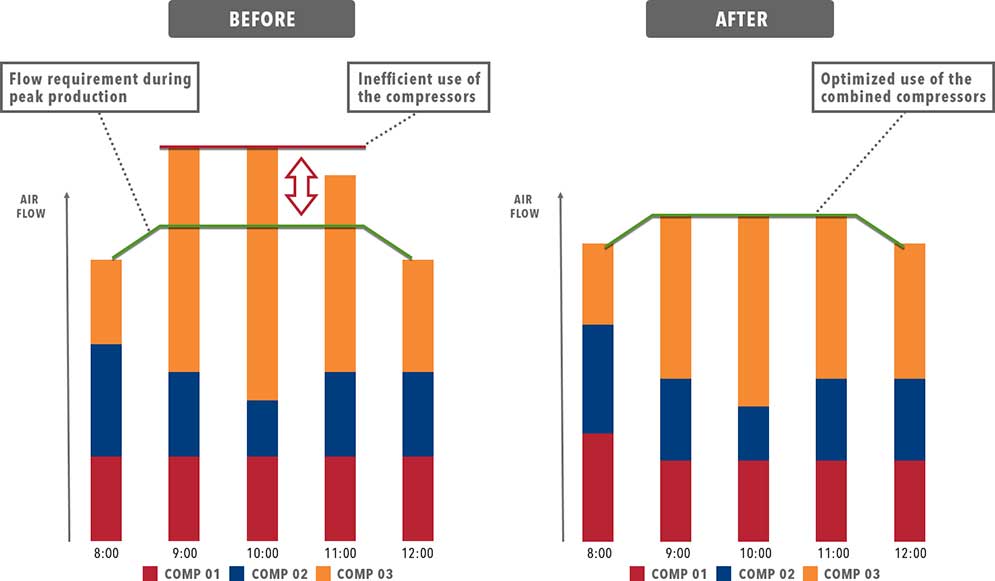

Multi-Compressor Control

Multi-compressor control significantly improves system efficiency in a distributed compressor system.

Our solution delivers centralized master control by applying optimization algorithms that reduce energy and maximize equipment output across the compressed air network.

Power monitoring tools provide information regarding energy usage. And built-in productivity reports deliver user-friendly insights about overall compressor system performance.

Anti-Surge Control

In a conventional system, anti-surge valves open within three seconds of detecting a surge condition to help prevent equipment failure. In addition, every time a valve is activated, air is released – and energy and production time are lost.

Our anti-surge control solution helps enhance compressor safety and efficiency.

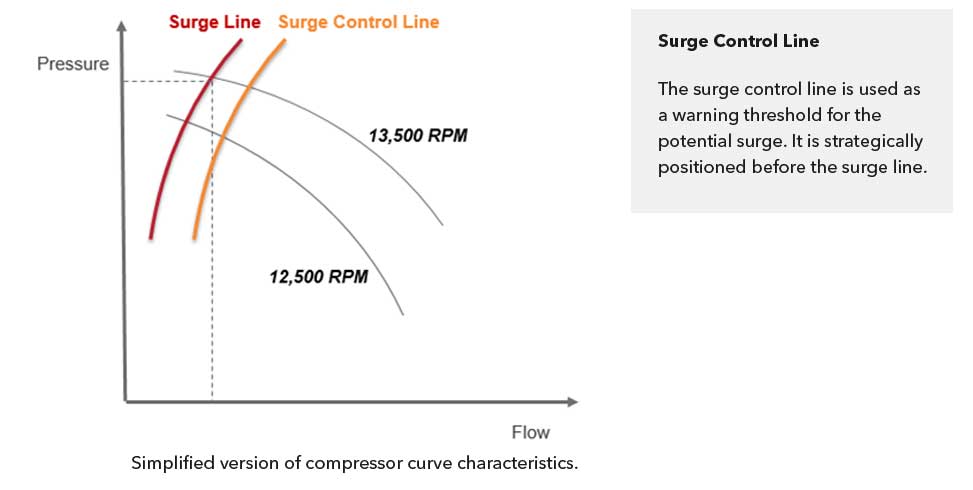

The solution is based on an advanced surge control algorithm that uses a dynamic setpoint value that is a function of the compressor’s operating point and surge control line values.

The function is designed to prevent the compressor from surging by opening the anti-surge valve in a more optimized way.

Conveyors can represent a single point of failure in a mine.

A poorly maintained conveyor may experience rapid belt wear and component failure, which can cause downtime – and negatively impact productivity and profits.

Automation & Material Management Optimization

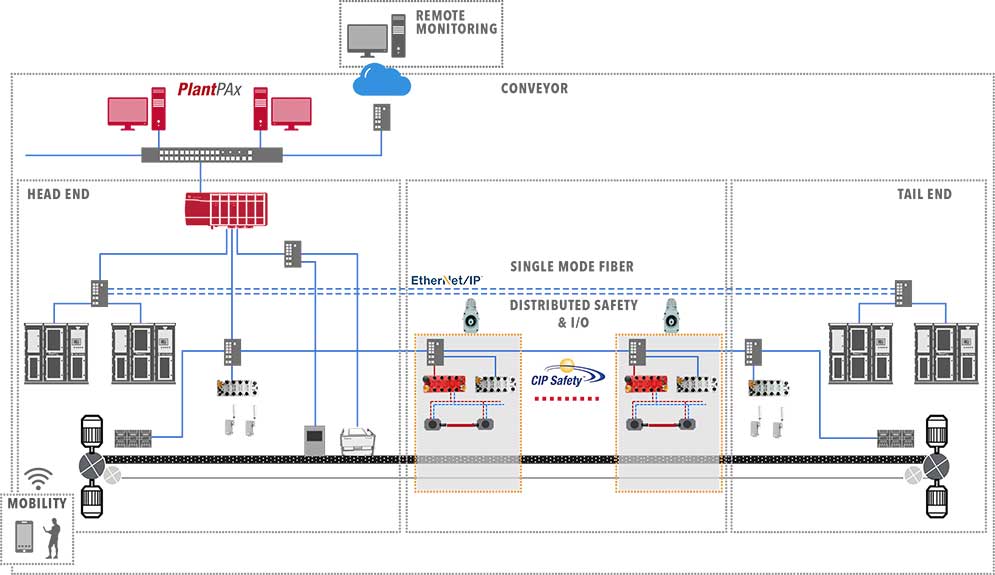

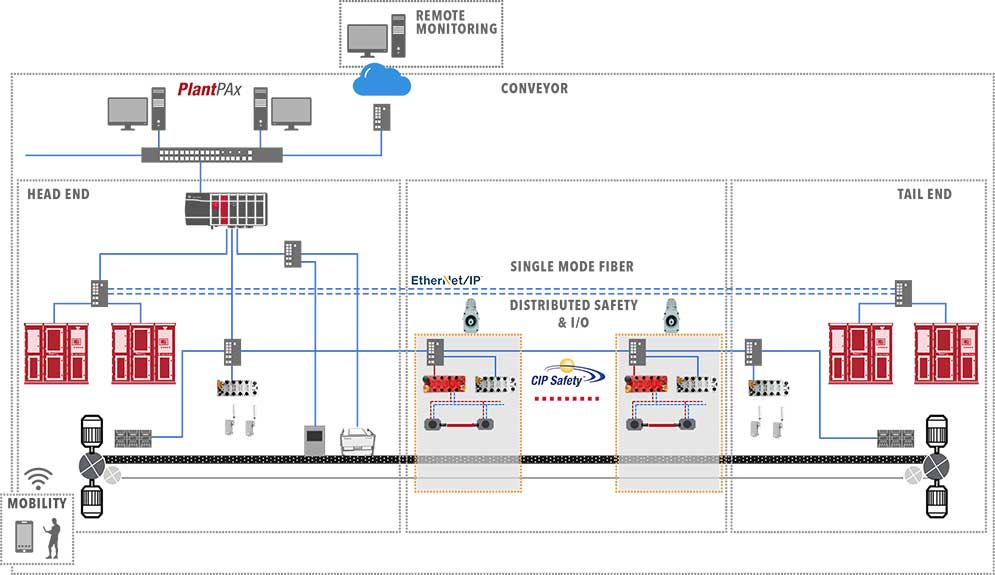

With integrated process control, safety, motor control and analytics, our architectures deliver benefits across mining operations.

Purpose-built process control is at the core of our mining architecture. Built on our PlantPAx® distributed control system (DCS), it delivers pre-engineered content for mine control, monitoring and reporting. It also incorporates modules developed for mining-specific challenges, including dedicated control strategies for material management:

- Tracking: Enables accurate product distribution along conveyors, optimizes the loading process, and helps avoid overload.

- Gap Control: Manages loading gaps across the system. It can safely and automatically switch a chute without tripping the belt when the clearance (gap) is present.

- Multiple Product Management: Simultaneously handles multiple products on the same conveyor by creating a controlled gap between the products. This increases belt throughput and operating efficiency.

Motor Management & Control

PowerFlex® MV and LV drives deliver high-performance speed and torque control to meet conveyor demands. Simplified integration with control systems helps speed design – and ease configuration, operation and maintenance.

Built for reliability, our drives feature a simple architecture and modular design – and provide harmonic mitigation, power factor correction and energy regeneration.

Drives with TotalFORCE® technology help improve conveyor performance and reduce downtime:

- Smooth load control: Applies motion profiles that reduce conveyor wear and tear – and save energy.

- Disturbances control: Isolated conveyor disturbances do not affect the drive, making output adjustments unnecessary.

- Load observer: Continuously monitors and compensates for normal conveyor mechanical wear.

- Adaptive tuning: Automatically identifies and suppresses potentially harmful resonance and vibration conditions.

- Predictive maintenance: Continuously monitors operation and remaining life of components based on actual operating conditions.

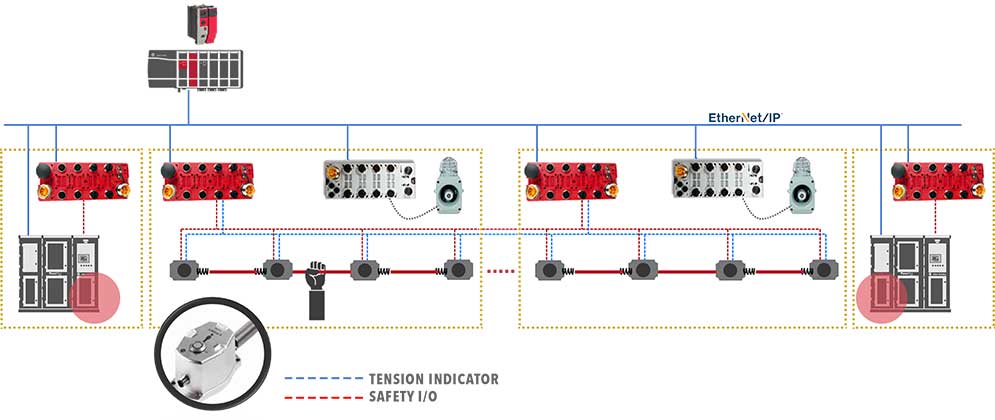

Integrated Safety

Our integrated safety solution for conveyors delivers safety requirements while reducing complexity and costs:

- Electromechanical components and associated wiring can be unnecessary. Safety-relevant signals can be transmitted via CIP Safety™ protocol over EtherNet/IP, reducing complexity and wiring costs.

- Distributed cabinets connect safety switches and traditional conveyor sensors using CIP Safety.

- GuardLogix® controllers, a single solution for standard and safety control, feature a high-performance CPU optimized for faster safety reaction time.

- Guard I/O™ safety modules offer the advantages of distributed I/O. Available in an IP67-rated package for EtherNet/IP.

- Microprocessor-based Lifeline™ 5 cable pull switches reduce false trips – and ease installation, diagnostics and repair.

- Safe Torque Off option for variable speed drives in applications where the de-energized state is considered the safe state. Removes rotational power to the motor without shutting down the drive.

Intelligent Asset Optimization

Keeping conveyor equipment operating optimally can be logistically challenging. You need access to the right information at the right time – and better ways to connect data.

We provide information-enabled solutions from device to enterprise:

- Dynamix™ integrated condition monitoring helps detect potential equipment failures before they occur.

- PowerFlex drives can enable predictive maintenance and minimize unplanned downtime by calculating the expected life of components based on actual operating conditions.

- FactoryTalk® Analytics™ LogixAI™ modules provide embedded analytics close to the equipment – no data scientist required.

- FactoryTalk InnovationSuite brings the power of the Industrial Internet of Things (IIoT) to your operations. Analyze equipment performance, predict failures and use augmented reality (AR) to provide real-time information to the field and enable remote collaboration.

Stackers and reclaimers are critical to mineral storage and blending operations.

These stockyard machines are typically specified for 20 years of operation – and must often run 24/7 in a harsh environment.

Automation Solutions for Stacker/Reclaimers

With our automation solutions, you can control your stacker/reclaimers in manual, semi-automatic or automatic mode – and integrate flexible technologies for machine positioning.

For example, an embedded GPS module in our control system provides GPS position in XYZ Cartesian LLA (latitude, longitude and altitude) format and speed (m/s).

Our solutions also enable seamless network integration with both Rockwell Automation devices and third-party equipment, including radios, belt scales, video cameras, encoders and sensing technologies.

For motor control, count on PowerFlex drives for smooth acceleration and deceleration – and less wear and tear on drive components. In addition, our drives feature predictive diagnostics and maintenance settings that can monitor drive and motor operating conditions to help analyze system health.

Mines generate valuable data - but it often exists in silos.

This means interdependences and trends that could improve decision making are missed.

Mine-to-Market Integration

FactoryTalk InnovationSuite makes it easy to connect data so you can improve operational insight across your business.

Collect

Capture data in real time from your existing systems, software, and assets.

Contextualize

Identify patterns, trends, and co-dependencies between activities like energy use, productivity, and quality.

Deliver

Visualize metrics from a single version of the truth with consolidated KPI correlations and cascading metrics.

Simulation and Digital Engineering

Business process simulation

Analyze your system’s behavior over time, ask "why" and "what if" questions, and test new designs or improvements without the risk.

Virtual commissioning and throughput simulation

Create models of equipment by adding physics to CAD and linking to process control code. Virtually commission and train workers before the physical build even takes place.

Equipment prototyping

Test equipment with different controls and operating logic. Verify synchronization, flow, sequencing, and functionality before committing to physical builds.

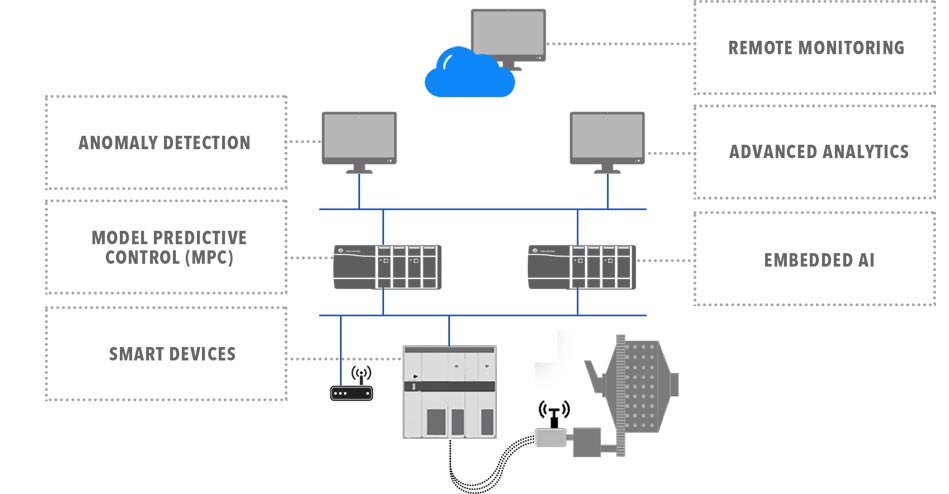

Scalable Analytics

Answer critical questions across your operations with:

- Smart devices: Predict potential failures of internal components

- Embedded AI: Define a problem and let the system find the solution: no data scientist required

- Model predictive control: Achieve multi-objective optimization: variability, recovery, reagent consumption, energy, throughput

- Anomaly detection: Identify unexpected items or events in data sets

- Advanced analytics: Design complex analytical processes

And, you don’t have to be on site to reap the benefits. Monitor equipment and collect valuable performance analytics securely from afar with remote monitoring capabilities. See an example of how we're enabling this with a key mining OEM.

Digitally-Enabled Workforce

Real-time information

Overlay real-time information onto your actual system for better situational awareness.

Remote collaboration

Allow experts and technicians to mark up live views to highlight details or guide multi-step solutions.

Expert capture

Transform expert knowledge into a reusable learning resource for your workforce. Create powerful step-by-step augmented reality instructions—and help frontline workers get their jobs done quickly and accurately.

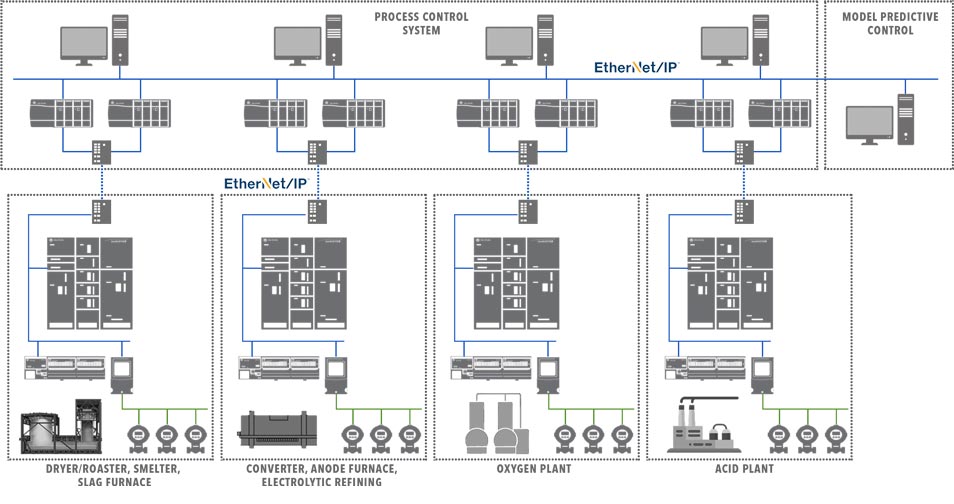

Smelting and metal refining includes a range of challenging processes like high‐temperature chemical reactions and electrorefining. If not properly managed, these processes consume excess energy and can wreak environmental havoc.

Metal Smelting & Refining

Our PlantPAx® DCS is a high-performance system that can handle complex applications like metal smelting & refining:

- Open design makes it easy to integrate to your business systems and keep information flowing

- High-availability architectures keep critical applications online

- Ability to make online changes

- Powerful and seamless integration with field instrumentation and 3rd party equipment

- Advanced control functionalities like integrated Model Predictive Control and AI

- Unified platform for processing and equipment

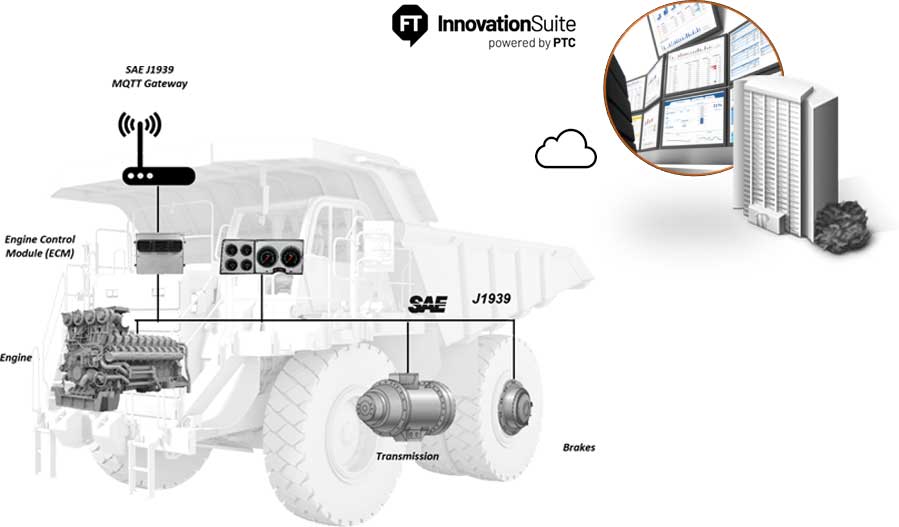

A typical global mining company uses thousands of machines: trucks, loaders, dozers, drills, excavators, and more.

Collecting and interpreting information from mobile assets is an essential part of the effective operation of a mine.

Mobile Asset Data Collection

The solution is based on 3 main components:

Vehicle onboard communications

Extract the data from the mobile equipment. The solution is designed to gather information from the machine ECM (and other sub-systems) — usually based on

SAE J1939 (most widely used) or other proprietary protocols.

Wireless transmission via modern IoT technologies

Once the information is available, the machine protocol is converted so it can be transmitted wirelessly, for example, using MQTT protocol.

MQTT is a low-power, small-code protocol that’s ideal for machine communications in constrained network environments

Powerful data aggregation and visualization

FactoryTalk® InnovationSuite solution gathers the data, aggregates it, and displays it so decision makers can leverage information and make smart business decisions.